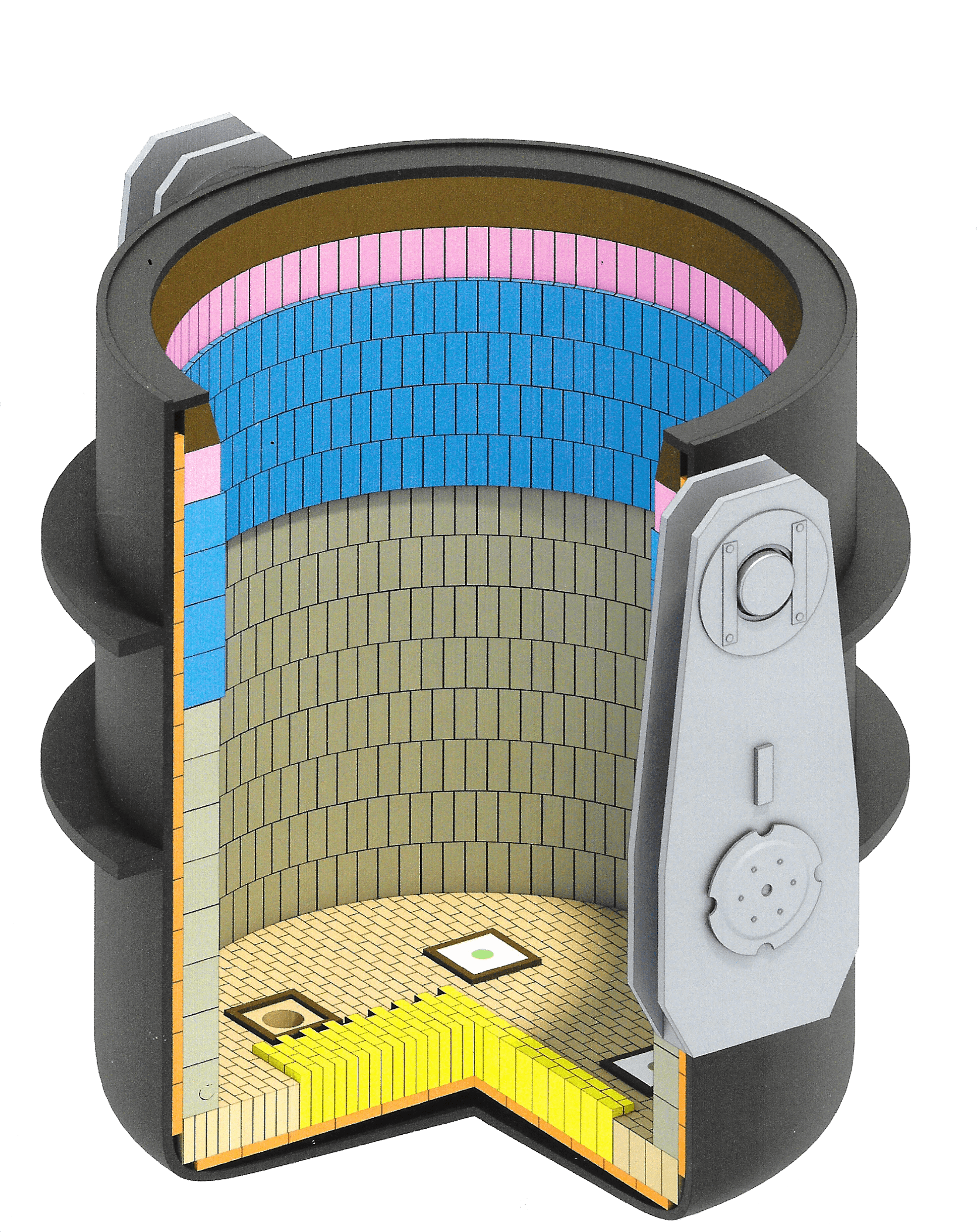

Steel Ladle

We come from the steel and we are Krosaki distribution company in the heart of Europe, dedicated to serve the Iron and Steel industry in Europe. With over 100 years developing refractories technology in Japan, we have now created the ultimate refractory solution for our European Steel customers, by fully aligning refractory & steel making goals in complete clarity and transparency thanks to our new strategy, the TCO Kaizen Strategy.

The steel ladle transports the liquid steel from the furnace to the continuous casting machine.

Safety Lining

Andalusite based High Alumina products are commonly used in the ladle safety lining due to their excellent volume stability, thermal and thermos-mechanical properties (high thermal shock resistance and low thermal conductivity)and neutral behavior towards molting metal.

TRL Hial 60, Andalusite and Corrundum based High Temperature fired Alumina Bricks

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Impact Zone

The operational features for the Impact zone are:

- Repeated heating and cooling so needs high spalling resistance.

- Long term usage (no repair during service) so needs volume stability.

- Purging by inactive gas, abrasion (bottom bricks are worn by impact during tapping) so need abrasion resistance.

TRL AMC7, Al - MgO - C

AMC 80, Al - MgO - C

AMCwi-100T, Al - MgO - C

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Metal zone

The operational features for the Metal Zone are:

- Repeated heating and cooling so needs high spalling resistance.

- Long term usage (no repair during service) so needs volume stability.

- Purging by inactive gas, abrasion (bottom bricks are worn by impact during tapping) so need abrasion resistance.

TRL HMR LM, EF MgO

BC605, Sinter / EF MgO

MITCAR 94M307X, EF MgO

TRL Dolo 5R1-RE, Doloma

TRL SLM2, Fused Alumina

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Metal zone

The operational features for the Metal Zone are:

- Repeated heating and cooling so needs high spalling resistance.

- Long term usage (no repair during service) so needs volume stability.

- Purging by inactive gas, abrasion (bottom bricks are worn by impact during tapping) so need abrasion resistance.

TRL HMR LM, EF MgO

BC605, Sinter / EF MgO

MITCAR 94M307X, EF MgO

TRL Dolo 5R1-RE, Doloma

TRL SLM2, Fused Alumina

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Freeboard

Refractories for the Freeboard area must cope with severe oxidation (bricks are usually exposed to air) and severe spalling (wide temperature variation). The Krosaki refractories are designed to improve oxidation resistance by adding anti-oxidants. Our MgO-C bricks are recommended to show good spalling resistance. Corrision is not so severe as slag or molten steel does not usually come into contact with the freeboard bricks.

TRL HMR LS, EF MgO

AC509, Sinter / EF MgO

MITCAR 94M710X, EF MgO

TRL HMR LM, EF MgO

BC605, Sinter / EF MgO

MITCAR 94M307X, EF MgO

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Freeboard

Refractories for the Freeboard area must cope with severe oxidation (bricks are usually exposed to air) and severe spalling (wide temperature variation). The Krosaki refractories are designed to improve oxidation resistance by adding anti-oxidants. Our MgO-C bricks are recommended to show good spalling resistance. Corrision is not so severe as slag or molten steel does not usually come into contact with the freeboard bricks.

TRL HMR LS, EF MgO

AC509, Sinter / EF MgO

MITCAR 94M710X, EF MgO

TRL HMR LM, EF MgO

BC605, Sinter / EF MgO

MITCAR 94M307X, EF MgO

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Freeboard

Refractories for the Freeboard area must cope with severe oxidation (bricks are usually exposed to air) and severe spalling (wide temperature variation). The Krosaki refractories are designed to improve oxidation resistance by adding anti-oxidants. Our MgO-C bricks are recommended to show good spalling resistance. Corrision is not so severe as slag or molten steel does not usually come into contact with the freeboard bricks.

TRL HMR LS, EF MgO

AC509, Sinter / EF MgO

MITCAR 94M710X, EF MgO

TRL HMR LM, EF MgO

BC605, Sinter / EF MgO

MITCAR 94M307X, EF MgO

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Slag zone

Slag line materials must be selected according to the specific conditions. Improved usage comes from applying high purity of MgO and the combination of several anti-oxidants. Damage factors of slag line bricks is corrosion by slag and oxidation (gas-phase, liquid phase).

TRL HMR LS, EF MgO

AC509, Sinter / EF MgO

MITCAR 94M710X, EF MgO

TRL Dolo RB 810, Doloma

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Bottom

The operational features for the Steel Ladle Bottom are:

- Repeated heating and cooling so needs high spalling resistance.

- Long term usage (no repair during service) so needs volume stability.

- Purging by inactive gas, abrasion (bottom bricks are worn by impact during tapping) so need abrasion resistance.

TRL HMR LB,EF MgO

LC310, Sinter / EF MgO

MITCAR 94M307X, EF MgO

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Porous Plug Well Block

Details of the porous plug well block.

Nozzle Well Block

Check out more regarding the Krosaki range of refractories for the Nozzle Well Block.

Safety lining

Andalusite based High Alumina products are commonly used in the ladle safety lining due to their excellent volume stability, thermal and thermos-mechanical properties (high thermal shock resistance and low thermal conductivity)and neutral behavior towards molting metal.

TRL Hial 60, Andalusite and Corrundum based High Temperature fired Alumina Bricks

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]

Safety lining

Andalusite based High Alumina products are commonly used in the ladle safety lining due to their excellent volume stability, thermal and thermos-mechanical properties (high thermal shock resistance and low thermal conductivity)and neutral behavior towards molting metal.

TRL Hial 60, Andalusite and Corrundum based High Temperature fired Alumina Bricks

*for more detailed information please contact us on +31 251 22 8030 or email [email protected]