Our Vision

Refractory Materials, as consumables, account for around 3% of steel production cost. However, they have much greater indirect influence on quality in the production of steel, including stability, productivity and elaboration of steel grades at different levels (chemistry and inclusion control).

Changes in the steel production process, demands the supply of natural resources/energy, environmental regulations, and a fundamental understanding of wear mechanisms. These are key factors affecting development of refractory technology.

STEEL REFRACTORIES - STRUCTURAL INTERDEPENDENCE

WE COME FROM THE STEEL

Martin Urcola

CEO Krosaki Europe BV

More information

We believe in serving the steel industry in Europe with an honest, fair and long term vision; following the example of our Group identity in the Japanese steel industry for more than 100 years.

The Krosaki TCO Kaizen Strategy is the ultimate win-win solution designed for our Steel partners in Europe. Based on providing a complete in-house refractory range for the steel objects and integrating the refractory costs transparently. Our guarantee is a quality, proven and cost efficient refractory solution for the Steel Group Leaders in Europe.

Krosaki group at a glance

We come from the steel as our parent company is Nippon Steel Corporation, in Japan. Our main difference, within the top 5 of refractory producers worldwide, is that our company is dedicated to, and focused on, the Steel industry.

PRIMARY BUSINESS

Refractory production & sales

CAPITAL

5,538 million Yen

EMPLOYEES

Consolidated - 4,460 Non-consolidated - 1,346

Name

Krosaki Harima Corporation

98% Dedicated to the STEEL Industry

CONSOLIDATED COMPANIES

16 (5 domestic, 11 overseas)

PARENT COMPANY

Nippon Steel Corporation (43%)

FOUNDED

14th October 1918

ESTABLISHED

1st June 1919

The Krosaki technology strategic plan, shares technology and best practices from Japan to our manufacturing plants in China, India and Spain, to optimize your supply chain and reduce risks.

Krosaki Europe offers a unique one stop shop solution for our European customers to access the full range from Krosaki production plants. Support is provided by a world leading technical network with our own experienced local technical service engineers in each steel plant. Commercial and logistics support comes from local field offices and our central headquarters in the Netherlands; complimenting the technical team to provide everything needed all under one single contract.

We care about your steel

Krosaki Harima Europe B.V., a member of the Krosaki group with headquarters in Japan, is a fast-growing company responsible for the distribution of group products for the steel industry in more than 13 European countries.

As the team expands you can get to know them here on the teams section. You will see a rich collection of nationalities and backgrounds which helps us offer our local and specific support across Europe.

TCO Kaizen Strategy

Krosaki has designed the TCO Kaizen Strategy as a service to Global Steel Groups with cross-regional production units.

Our company counts on proven refractories technology for all consumable refractories used in Iron and Steel manufacturing. With access to products in over 20 refractory production plants, we have the ability to complete the refractory range by Steel Object, optimizing the local sourcing solutions.

We have the technological knowledge, decades of experience, more refractory production plants close to steel plants and a dedicated local team of technical service engineers in each steel plant. We are now able in Europe to apply for the first time the Krosaki Kaizen model; Standardizing the refractory methodology and offering a cost/performance solution.

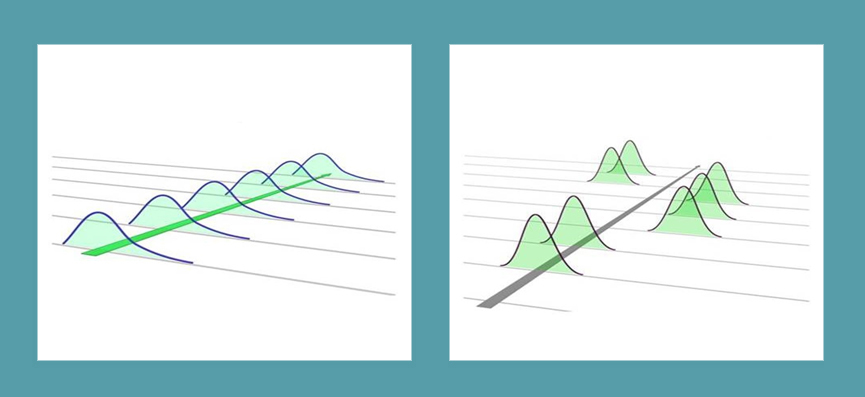

Krosaki Kaizen Model

The Krosaki Kaizen model takes a structured and methodical refractory approach by completing the refractory range for each steel object, allowing our customers to benefit from a cost/performance solution.

Krosaki applies this system to all steel plant objects.

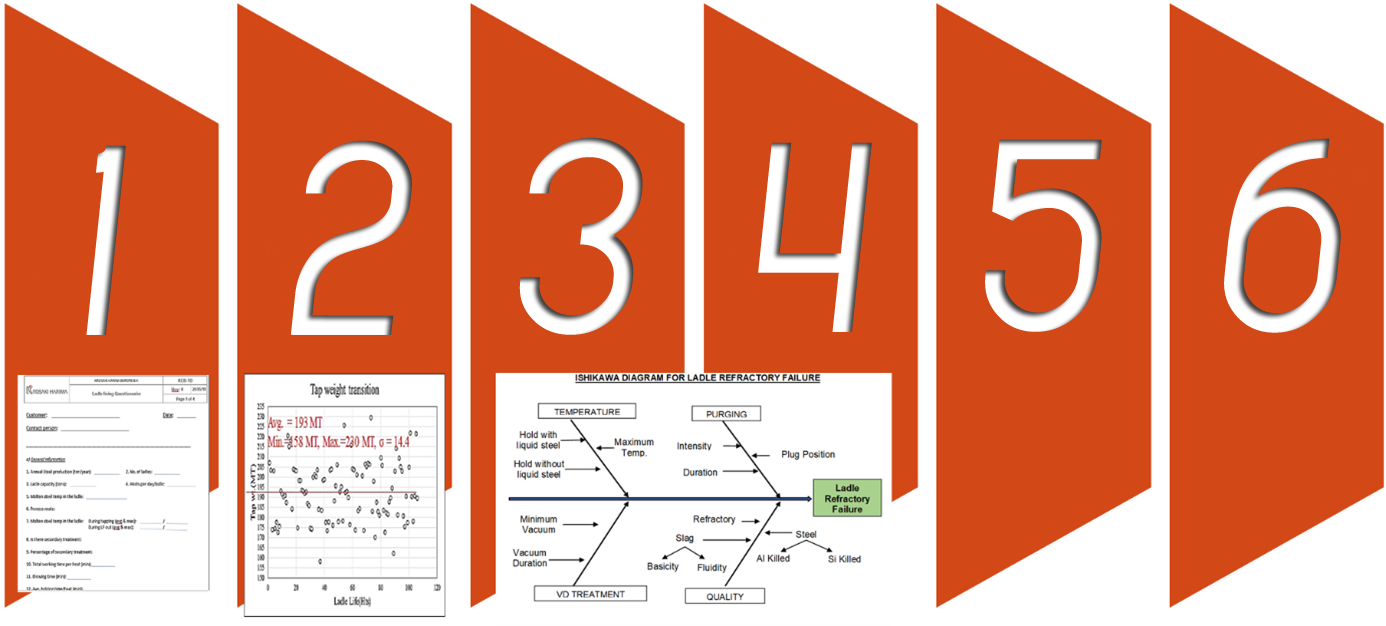

Step 1. Collection of Data. Using Krosaki Kaizen Format.

Step 2. Analysis of Data. Using Krosaki Kaizen Tools.

Step 3. Selection of the best possible lining profile and materials.

Step 4. Trial. 24/7 monitoring and preparation of reports.

Step 5. Further improvements as the KAIZEN activity.

Step 6. Improvement in the first year TCO/CPT orientated.

These six steps close the Kaizen loop.

Published Academic Papers

We have a wealth and depth of knowledge here at Krosaki and think sharing it is the right way forward. We now have a dedicted page to ‘Published Academic Papers’ where you can increase your knowledge relating to refractories. There is even the opportunity to have the papers’ creator contact you if you request it. We will be releasing a new paper every two weeks so keep checking back, with the OBJECT FOCUS changing over time. Previous papers will be available in the archive.

OBJECT FOCUS: Torpedo Car & Hot Melt Ladle

News

Refractory Highlights Conference is back for 2024 for the steel industry

The famous Refractory Highlights Conference is back in 2024, with the focus on ‘Greener metal making with refractories’. We are very pleased to announce that we are again holding our leading conference for the Nordic countries in Sweden. The close cooperation with...

Proud to be back – Refractory Highlights Converence

After our Covid enforced break we are very pleased to announce that we are again working in close cooperation with Bet-Ker Oy on the 2023 Refractory Highlights Conference on May 24th and 25th. So far there are more registrants that previous years, great motivation to...

Steely resolve: Krosaki Harima focused on ESG best practices

Having supplied the steel industry for more than a century, today Krosaki Harima Corporation is focused on expanding its global operations in line with Environmental, Social, and Governance (ESG) best practices. Since it was established in 1918, Krosaki Harima...

Press Release – Notice on the Conclusion of Partnership Agreement with ArcelorMittal Refractories

Krosaki Harima Corporation (with headquarters located in Kitakyushu, Japan) operating within the Nippon Steel Group informs that they have signed a partnership agreement with ArcelorMittal Refractories (with headquarters located in Kraków, Poland), part of the...

New challenges in steel manufacture

We are always taking on new challenges to achieve sustainable, responsible and ethical growth with our customers. We follow guidance from Krosaki Harima Corporation: The destruction of the environment continues on a global scale today, and we, as a corporate citizen...

Krosaki new online presence

Our new digital strategy is here with a new public website KrosakiSTEEL, online learning platform - KrosakiKNOWLEDGE and private object portal for the top steel groups in Europe - KrosakiSHARING. The interdependence between refractories and steel making is clear, our...

Technical office (junior) engineer

As a Technical Office (Junior) Engineer, you will contribute to the success of steel plants by providing technical support in the selection, design, and application of refractory materials. Your work will ensure the optimization of industrial processes and equipment...

Health Safety Environment Officer

Join us in driving sustainable practices within the steel industry. As an HSE Officer, you will responsible for initiatives to ensure compliance with health, safety, and environmental regulations, while supporting the transition of the industry towards Green Steel...

Business and Logistics Operations Support

Vanuit ons hoofdkantoor in Noord-Holland en regionale kantoren door heel Europa bieden wij technische, logistieke en verkoopondersteuning voor de door Krosaki-groep geproduceerde vuurvaste materialen over de hele wereld. Het hoofdkantoor van de groep bevindt zich in...

Business and Logistics Operations Support

Krosaki group manufactures and sells refractories since its establishment in 1919 using state-of-the-art technology, demonstrating respect to the law and sensitivity to global environmental problems. The location of our office is in Velsen-Noord . We are looking for a...

Technical Sale Support (Germany)

From our main office in North Holland and regional offices throughout Europe we provide technical, logistical and sales support for the refractories manufactured by Krosaki throughout the world. Group headquarters being in Japan. Our growth is achieved by...

Technical Sales Support

Wij zijn op zoek naar een nieuwe collega voor de uitbreiding van ons technische team. Als onderdeel van ons team ondersteun je Krosaki en help je onze voortdurende groei bij onze gewaardeerde klanten te realiseren. Leren op de werkplek zal een belangrijk onderdeel...

Technical Sales Support

By joining our team you will be supporting Krosaki and helping to realize our ongoing growth with our valued customers. On-the-job learning will be a key part of your development at Krosaki, both at the Main office and at the major steel producers in...

Can you see clearly?

Refractory managers in the steel unit are often tasked with purchasing, logistics, stock control, quality control follow up, development of qualities, troubleshooting, etc. making them time poor.

Dealing with so many references and so many suppliers for each reference makes Refractory Management very complicated.

The TCO Kaizen Strategy is focused on the Steel Object refractory approach instead of the individual refractory approach – simplification and a change of focus.

Secondly, completing the refractory range of the steel object by the Refractory partner. The focus becomes the stability, performance & cost optimization of the steel object refractories via the Krosaki Kaizen Model.

Then, we work together with the Steel Group and plant to optimize resources in partnership. Transparency, aligned data sharing goals, technical services & troubleshooting responsibilities, confidentiality, cost monitoring and reporting are all part of the TCO Kaizen Strategy.